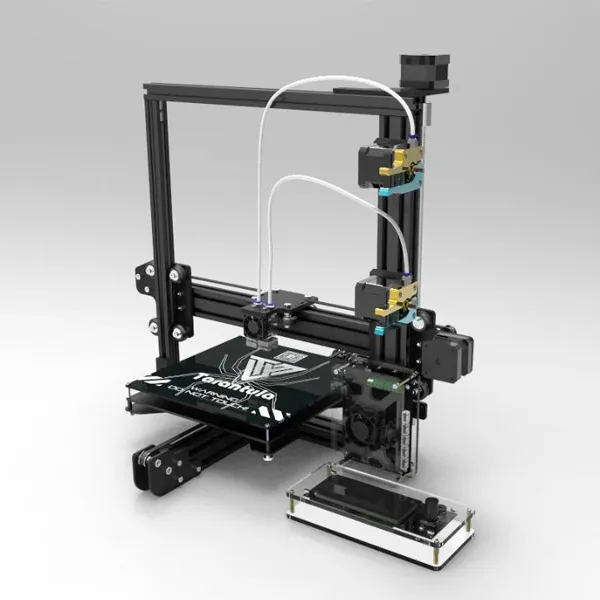

What is the Tevo Tarantula Pro Kit

The Tevo Tarantula Pro Kit is a popular choice for hobbyists and 3D printing enthusiasts looking for an affordable yet capable 3D printer. This DIY kit allows users to assemble their own printer, providing a hands-on experience and a deeper understanding of 3D printing technology. Known for its ease of assembly and open-source nature, the Tevo Tarantula Pro offers a great entry point into the world of additive manufacturing, as well as a platform for customization and upgrades. The kit includes all the necessary components, from the frame and electronics to the print bed and extruder. This self-assembly approach allows users to learn the inner workings of their printer and customize it to their specific needs. The Tevo Tarantula Pro has gained a reputation for its reliability and value, making it a favorite among beginners and experienced users alike. Its combination of affordability, features, and community support makes it a standout choice in the desktop 3D printer market.

Overview of the Tevo Tarantula Pro Kit

The Tevo Tarantula Pro Kit is a DIY (Do-It-Yourself) 3D printer kit designed for users who enjoy building and tinkering with technology. It’s a fused deposition modeling (FDM) printer, which means it works by melting and extruding plastic filament to create three-dimensional objects layer by layer. This kit comes with all the necessary components and detailed instructions, allowing users to assemble the printer from scratch. The process of assembling the Tevo Tarantula Pro is a great way to understand how 3D printers work. It offers a learning experience beyond just printing. The kit’s open-source design also encourages users to experiment with modifications and upgrades, fostering a strong community of support and shared knowledge. The printer is known for its robust build quality and reliability, making it a dependable choice for both beginners and experienced users. The straightforward assembly process, combined with its ability to produce high-quality prints, makes the Tevo Tarantula Pro a strong contender in the budget-friendly 3D printer market.

Key Specifications of the Tevo Tarantula Pro Kit

The Tevo Tarantula Pro Kit boasts several impressive specifications that contribute to its popularity. It typically features a build volume of approximately 220 x 220 x 240 mm, providing ample space for printing various objects. The printer supports a range of filament types, including PLA, ABS, PETG, and TPU, allowing users to experiment with different materials based on their project requirements. It also includes a heated bed, which is essential for ensuring proper adhesion of the first layer and preventing warping, particularly when using ABS. The printer’s dual Z-axis design enhances stability and print quality, resulting in more precise and consistent prints. The inclusion of a color touchscreen interface simplifies operation and provides a user-friendly experience. The printer typically uses a 0.4mm nozzle, which is a standard size offering a balance between print speed and detail. The power supply is designed to be reliable and safe, providing the necessary power for all components. These key specifications combine to make the Tevo Tarantula Pro a versatile and capable 3D printer suitable for a variety of projects and users.

Feature 1 Enhanced Build Plate

The enhanced build plate is a critical feature of the Tevo Tarantula Pro Kit, contributing significantly to print quality and user experience. The build plate is the surface on which the 3D prints are created, so a stable and well-prepared surface is essential for successful prints. The enhanced build plate typically includes a heated bed, which is crucial for preventing warping and ensuring proper adhesion of the first layer of the printed object. This is especially important when printing with materials like ABS. The build plate is usually constructed from a durable material, ensuring it can withstand the heat and wear and tear of the printing process. This feature allows for a more reliable and consistent printing experience, reducing the risk of print failures and making it easier for users to achieve high-quality results. The heated bed also helps in achieving better layer adhesion. It prevents the corners of your prints from lifting off the bed during the printing process, something that is very common with ABS.

Benefits of the Heated Bed

The heated bed on the Tevo Tarantula Pro Kit offers several significant benefits that directly impact the quality and success of 3D prints. One of the most important advantages is its ability to prevent warping. Warping occurs when the printed object cools unevenly, causing the corners and edges to lift off the build plate. The heated bed maintains a consistent temperature, reducing the temperature gradient and minimizing the chances of warping. Another key benefit is improved adhesion. The heated bed helps the first layer of the filament to adhere firmly to the build plate. This ensures that the print starts correctly and remains in place throughout the printing process. This is particularly critical for materials like ABS, which require higher bed temperatures for optimal adhesion. The heated bed also improves the overall print quality. By providing a stable and consistent printing environment, it leads to smoother surfaces, better layer adhesion, and more accurate dimensions, which in turn will make your 3D prints look perfect. This results in a more reliable and user-friendly 3D printing experience overall.

Tips for Leveling the Build Plate

Leveling the build plate is a crucial step in the setup process of the Tevo Tarantula Pro Kit, and it directly impacts the quality of your 3D prints. Start by ensuring the build plate is clean and free of debris. Many users also find it helpful to use a thin layer of adhesive, such as glue stick or painter’s tape, on the build plate. When leveling, use the provided leveling screws to adjust the height of the bed at each corner. The goal is to have a consistent distance between the nozzle and the build plate across the entire surface. Many users print a test pattern (like a square or a series of lines) to check the first layer adhesion. If the nozzle is too close to the bed, the filament will not extrude properly. If the nozzle is too far from the bed, the filament will not adhere. Adjust the bed level until the filament lays down smoothly and adheres well. You can also use a piece of paper to calibrate the nozzle height. Slowly lower the nozzle until it just barely grips the paper as you move it around. A properly leveled bed will significantly improve the quality of your prints, reduce the risk of print failures, and make the whole 3D printing process more enjoyable.

Feature 2 Dual Z-Axis Design

The Dual Z-Axis design is a standout feature of the Tevo Tarantula Pro Kit, enhancing its stability and print quality significantly. The Z-axis controls the vertical movement of the print head, and having two independent Z-axis motors and lead screws means the print head is supported on both sides. This dual support system distributes the weight more evenly, reducing the likelihood of the print head wobbling or tilting during printing. This enhanced stability leads to more precise and consistent layer alignment, resulting in higher-quality prints with fewer defects. The dual Z-axis design also minimizes the effects of vibrations, leading to smoother surfaces and more accurate dimensions. This feature is particularly beneficial when printing taller objects, as it prevents the print head from sagging or leaning as it moves upward. By providing a more stable platform for the print head, the dual Z-axis design ensures that the Tevo Tarantula Pro delivers reliable and high-quality prints, making it a step above the competition in its price range. The Dual Z-axis is a great addition to the machine.

Advantages of Dual Z-Axis for Stability

The advantages of the Dual Z-Axis design in the Tevo Tarantula Pro Kit are substantial, primarily related to stability and print quality. The dual Z-axis system provides a more balanced and stable platform for the print head, minimizing the wobble and tilt. This increased stability ensures that the layers are consistently aligned, leading to more accurate and higher-quality prints. The dual Z-axis design reduces the risk of layer shifting, where the layers of the print are misaligned, causing defects and compromising the structural integrity of the object. Furthermore, the enhanced stability reduces the impact of vibrations, which can negatively affect print quality. The vibrations can cause ripples and inconsistencies on the surface of the print. The dual Z-axis minimizes these effects, resulting in smoother surfaces and more detailed prints. This design is especially advantageous when printing taller objects. The weight of the print head is supported more evenly, reducing the likelihood of sagging or leaning. This leads to more accurate dimensions and a more reliable printing experience. Overall, the dual Z-axis design significantly contributes to the Tevo Tarantula Pro’s reputation for producing high-quality, reliable prints.

Maintenance Tips for Z-Axis

Maintaining the Dual Z-Axis system on the Tevo Tarantula Pro Kit is essential to ensure its continued performance and reliability. Start by regularly lubricating the Z-axis lead screws with a suitable lubricant, such as lithium grease or a specialized 3D printer lubricant. This helps reduce friction and wear, ensuring smooth and consistent vertical movement. Regularly inspect the lead screws for any signs of damage or wear, such as scratches or bends. Clean the lead screws of any dust, debris, or old lubricant before applying fresh lubricant. Ensure that the Z-axis motors are properly aligned and securely mounted. Misalignment can cause binding and reduce the effectiveness of the dual Z-axis system. Check and tighten the set screws on the couplers that connect the Z-axis motors to the lead screws. Loose set screws can lead to slippage and inconsistent Z-axis movement. Periodically, you may also want to calibrate the Z-axis to ensure proper alignment and levelness. Following these maintenance tips will extend the lifespan of your Tevo Tarantula Pro’s dual Z-axis system and help you maintain high-quality prints. Regular maintenance helps in the smooth operation of the printer.

Feature 3 Color Touchscreen Interface

The color touchscreen interface is a modern and user-friendly feature of the Tevo Tarantula Pro Kit, enhancing the overall printing experience. This intuitive interface replaces the traditional LCD screen and rotary encoder found on many other 3D printers. The color touchscreen provides a clear and easy-to-navigate display, allowing users to control all aspects of the printer’s operation with simple taps and swipes. The interface typically displays real-time information about the print progress, temperature, and other critical settings. The color display makes it easier to monitor the printer’s status and identify any potential issues. This user-friendly interface makes the printer accessible to beginners. It reduces the learning curve associated with operating a 3D printer. With the touchscreen, users can easily load and unload filament, adjust print settings, and initiate prints directly from the printer. The color touchscreen interface also supports multiple languages, making the printer more accessible to a wider audience. This interface represents a significant improvement over older control methods and helps to create a more enjoyable and efficient 3D printing experience.

Ease of Use and Navigation

The ease of use and navigation offered by the color touchscreen interface of the Tevo Tarantula Pro Kit is a key advantage for users of all skill levels. The interface is designed to be intuitive and user-friendly, with a clear layout and simple controls. Navigating through the menus is easy, with responsive touch controls and clear visual cues. The main screen typically displays the current print status, including the progress, temperature, and estimated print time. Users can easily access and adjust settings such as print speed, nozzle temperature, and bed temperature with just a few taps. The touchscreen allows users to load and unload filament. You can also control the movement of the print head directly from the screen, making manual adjustments and maintenance tasks easier. The interface includes a built-in leveling guide, which simplifies the process of leveling the build plate. Overall, the intuitive design of the touchscreen interface significantly reduces the learning curve for new users and streamlines the 3D printing process. With its easy-to-understand layout and straightforward controls, the touchscreen makes the Tevo Tarantula Pro a joy to use for both beginners and experienced 3D printing enthusiasts.

Customization Options on the Touchscreen

The color touchscreen interface on the Tevo Tarantula Pro Kit often provides customization options, allowing users to personalize their printing experience. Users can typically adjust the display settings, such as brightness and color scheme, to their preference. Some interfaces allow users to customize the information displayed on the main screen, allowing them to prioritize the data they find most relevant. The touchscreen can often be updated with new firmware, which may add new features and improvements. Some interfaces allow users to upload custom icons or images to personalize the display. Customization options can extend to the user interface. You may able to change the language settings on the touchscreen. Users can also control advanced settings. Those include adjusting the Z-offset and fine-tuning the print parameters. These customization features enhance the user experience. It makes the Tevo Tarantula Pro more adaptable to individual preferences. This level of control contributes to a more personalized and enjoyable 3D printing experience. These features show how much more customizable a touchscreen can be compared to a regular LCD screen.

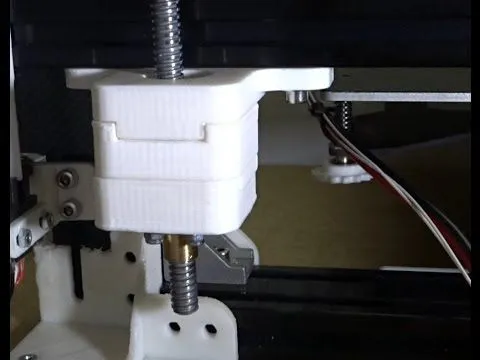

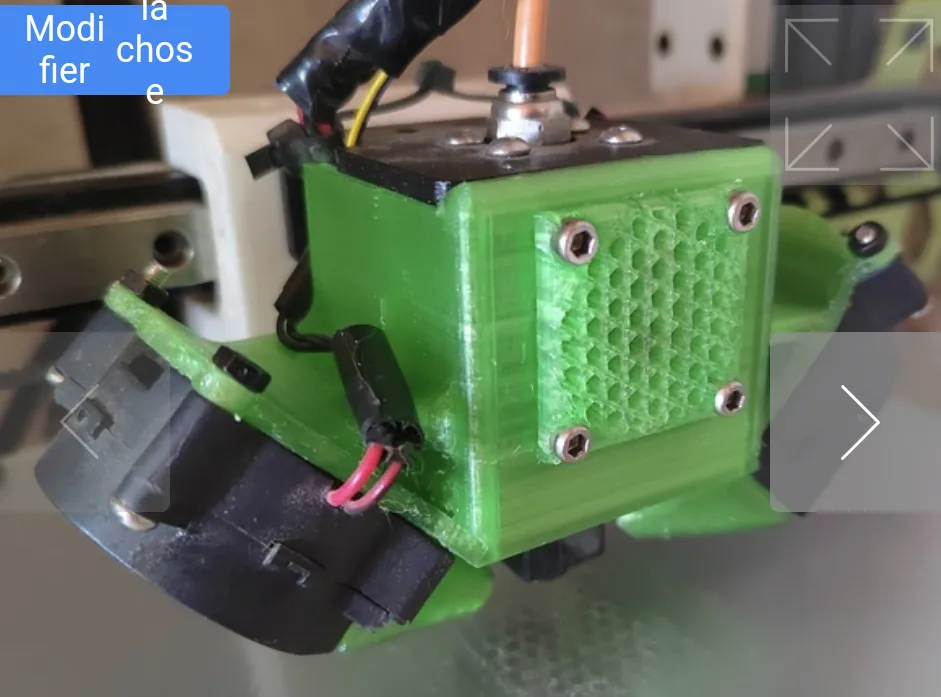

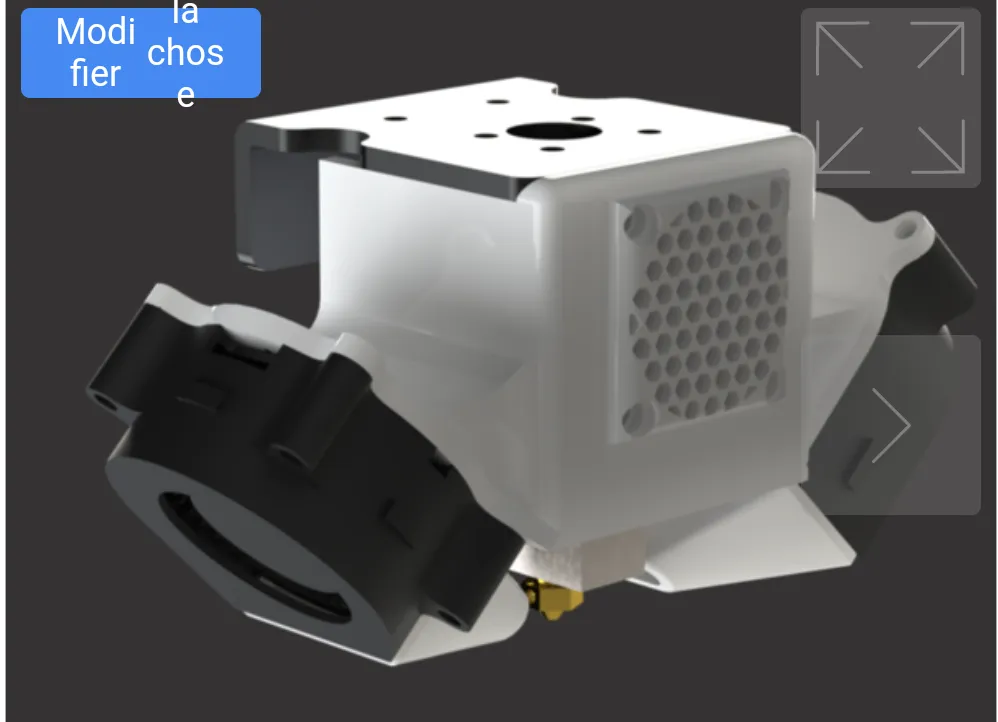

Feature 4 Upgraded Extruder System

The upgraded extruder system is a crucial feature of the Tevo Tarantula Pro Kit, directly impacting the printer’s performance and reliability. The extruder is responsible for feeding the filament into the hot end, where it is melted and extruded onto the build plate. An upgraded extruder system typically features improved components, such as a more robust motor, a better-designed filament feed mechanism, and a higher-quality hot end. These enhancements contribute to smoother and more consistent filament flow. This results in more precise and higher-quality prints. The upgraded extruder system is often more capable of handling a wider range of filament types, including flexible filaments and those that require higher printing temperatures. It can also improve the print speed. The upgraded extruder system helps to minimize the risk of clogging, a common problem that can interrupt the printing process. This feature makes the Tevo Tarantula Pro a more reliable and versatile 3D printer capable of producing high-quality prints with a variety of materials. It enhances the overall printing experience by improving performance and reducing the likelihood of print failures.

Performance and Reliability

The upgraded extruder system in the Tevo Tarantula Pro Kit significantly boosts its performance and reliability, making it a dependable choice for 3D printing enthusiasts. The improved components of the extruder system, such as a more powerful motor and a better-designed feed mechanism, ensure a consistent and reliable filament feed. This consistent flow of filament leads to more precise layer deposition, resulting in higher-quality prints with smoother surfaces and more accurate dimensions. The upgraded extruder system also reduces the risk of clogging, a common issue that can disrupt the printing process and lead to print failures. The improved heat distribution and thermal management within the hot end contribute to consistent melting and extrusion of the filament. This also enhances reliability. The improved performance allows the printer to operate at higher speeds. It can also maintain a high level of print quality. The reliability of the extruder system minimizes downtime and the need for frequent maintenance. All of this contributes to a more efficient and enjoyable 3D printing experience. The overall enhancements make the Tevo Tarantula Pro a robust and capable 3D printer.

Filament Compatibility

The filament compatibility of the upgraded extruder system in the Tevo Tarantula Pro Kit is a key aspect of its versatility. The improved design and performance of the extruder system allow it to work with a wide range of filament types, opening up a world of possibilities for 3D printing projects. The printer typically supports standard filaments, such as PLA, ABS, and PETG, which are the most commonly used materials in 3D printing. It can also handle more specialized filaments, such as TPU (flexible filament), which opens the door to printing items like phone cases and other flexible objects. The upgraded extruder system is often capable of reaching higher temperatures. It will enable the printing of materials like nylon and polycarbonate, which offer increased strength and durability. The ability to handle a diverse range of filaments allows users to choose the best material for their specific projects, based on properties like strength, flexibility, and temperature resistance. This expanded filament compatibility makes the Tevo Tarantula Pro a versatile and adaptable 3D printer, suitable for a wide range of applications and user requirements. This is an important feature of the printer.

Feature 5 Open-Source Design

The open-source design of the Tevo Tarantula Pro Kit is a significant advantage, fostering a vibrant community and providing users with extensive customization options. Open source means that the design files, firmware, and software are publicly available, allowing users to modify, improve, and adapt the printer to their specific needs. This open approach fosters innovation. Community members can share their modifications, upgrades, and improvements, creating a collaborative ecosystem of knowledge and resources. The open-source nature of the Tevo Tarantula Pro allows users to customize the printer. You can add new features, experiment with different settings, and tailor the printer to their specific requirements. It also allows users to upgrade components, such as the hot end, extruder, or build plate, to enhance the printer’s performance and capabilities. The open-source nature of the Tevo Tarantula Pro also promotes a strong community support network. It gives users a place to share their experiences, ask questions, and find solutions to common problems. This open-source approach encourages learning, experimentation, and collaboration. This makes the Tevo Tarantula Pro a truly adaptable and user-friendly 3D printer. It encourages users to learn and grow within the 3D printing hobby.

Benefits of Customization and Upgrades

The benefits of the open-source design of the Tevo Tarantula Pro Kit extend significantly to customization and upgrades, which allow users to tailor the printer to their specific requirements and preferences. Users can customize the printer by modifying its firmware, allowing them to adjust print settings, add new features, and optimize performance. Upgrades offer a way to improve the printer’s capabilities. You can swap out the hot end, extruder, or build plate. This will improve print quality and expand the range of materials that can be printed. Customization also allows users to personalize the appearance and functionality of the printer. They can add enclosures, lighting, or other accessories to enhance their printing setup. Customization can also provide for enhanced performance. This might involve adding auto-bed leveling, or other advanced features. This level of customization allows users to learn and experiment with different technologies. This deepens their understanding of 3D printing. The ability to upgrade the printer extends its lifespan. This ensures it remains a valuable tool for years to come. Overall, customization and upgrades make the Tevo Tarantula Pro Kit a versatile, adaptable, and rewarding 3D printing platform.

Community Support and Resources

Community support and resources are essential aspects of the Tevo Tarantula Pro Kit. The open-source nature of the printer fosters a vibrant community of users who actively share their knowledge, experiences, and modifications. This community provides extensive support and resources for users of all skill levels. Online forums and social media groups are popular places to find answers to questions, troubleshoot problems, and share ideas. Users can find advice, tips, and tutorials from other users, which simplifies the learning process and helps users to overcome challenges. Numerous online resources offer guides, tutorials, and troubleshooting tips. These resources cover various topics, from assembly and setup to advanced printing techniques. The community is active in developing and sharing modifications and upgrades for the printer. These range from firmware updates to new hardware components. The availability of community support and resources significantly enhances the user experience. It allows users to learn from others, find solutions to problems, and stay up-to-date with the latest advancements in 3D printing technology. The Tevo Tarantula Pro’s strong community support makes it a welcoming and rewarding platform for 3D printing enthusiasts.

Feature 6 Power Supply

The power supply unit (PSU) is a crucial component of the Tevo Tarantula Pro Kit, providing the necessary electrical power to operate the printer safely and reliably. A well-designed power supply is essential for consistent performance and safety during operation. The PSU converts AC (alternating current) power from the wall outlet into the DC (direct current) power required by the printer’s various components, such as the motors, heating elements, and control board. The power supply must provide sufficient power to all the components. It also maintains a stable voltage to prevent fluctuations that could affect print quality or damage the printer. The PSU typically includes safety features, such as over-current protection and short-circuit protection, to protect both the printer and the user. A high-quality power supply ensures that the printer operates safely and efficiently. It also contributes to the overall reliability of the 3D printing process. It is a critical part of the printer to ensure the printer is operational at all times.

Safety and Reliability

Safety and reliability are paramount aspects of the power supply unit (PSU) in the Tevo Tarantula Pro Kit. The PSU must adhere to stringent safety standards to protect both the user and the printer from electrical hazards. Key safety features include over-current protection, which prevents the PSU from delivering excessive current that could damage components or cause a fire. Short-circuit protection, which immediately shuts off power in the event of a short circuit. It prevents the flow of dangerous current. The PSU is typically housed in a protective enclosure. This helps prevent accidental contact with live electrical components. The PSU should be designed with high-quality components. They reduce the risk of failure and extend the lifespan of the unit. Reliability is also crucial, as a failing PSU can halt the printing process. It can also cause damage to the printer’s other components. A reliable PSU provides a stable and consistent power supply, ensuring that the printer operates smoothly and produces high-quality prints. The PSU is often certified by safety organizations. That is to guarantee that it meets safety requirements. Overall, a safe and reliable PSU is essential for a positive and worry-free 3D printing experience.

Power Efficiency

Power efficiency is a significant consideration in the design of the power supply unit (PSU) for the Tevo Tarantula Pro Kit, especially with the increasing emphasis on energy conservation and cost-effectiveness. A more efficient PSU converts AC power from the wall outlet to DC power with minimal energy loss, which reduces electricity consumption and can lower the overall operating costs. More efficient PSUs also produce less heat, which contributes to the reliability and longevity of the unit. A PSU with a higher efficiency rating will waste less energy as heat. This can lead to a more environmentally friendly operation. The power efficiency of the PSU can also impact the overall performance of the 3D printer. A stable and efficient power supply ensures that all components, including the heated bed and hot end, receive the required power without fluctuations. This allows for consistent temperatures and prevents issues such as thermal runaway. Choosing a power supply with a high-efficiency rating is an important factor. It ensures that the Tevo Tarantula Pro operates safely, reliably, and cost-effectively. Power efficiency is often displayed as a percentage, with a higher percentage indicating greater efficiency.

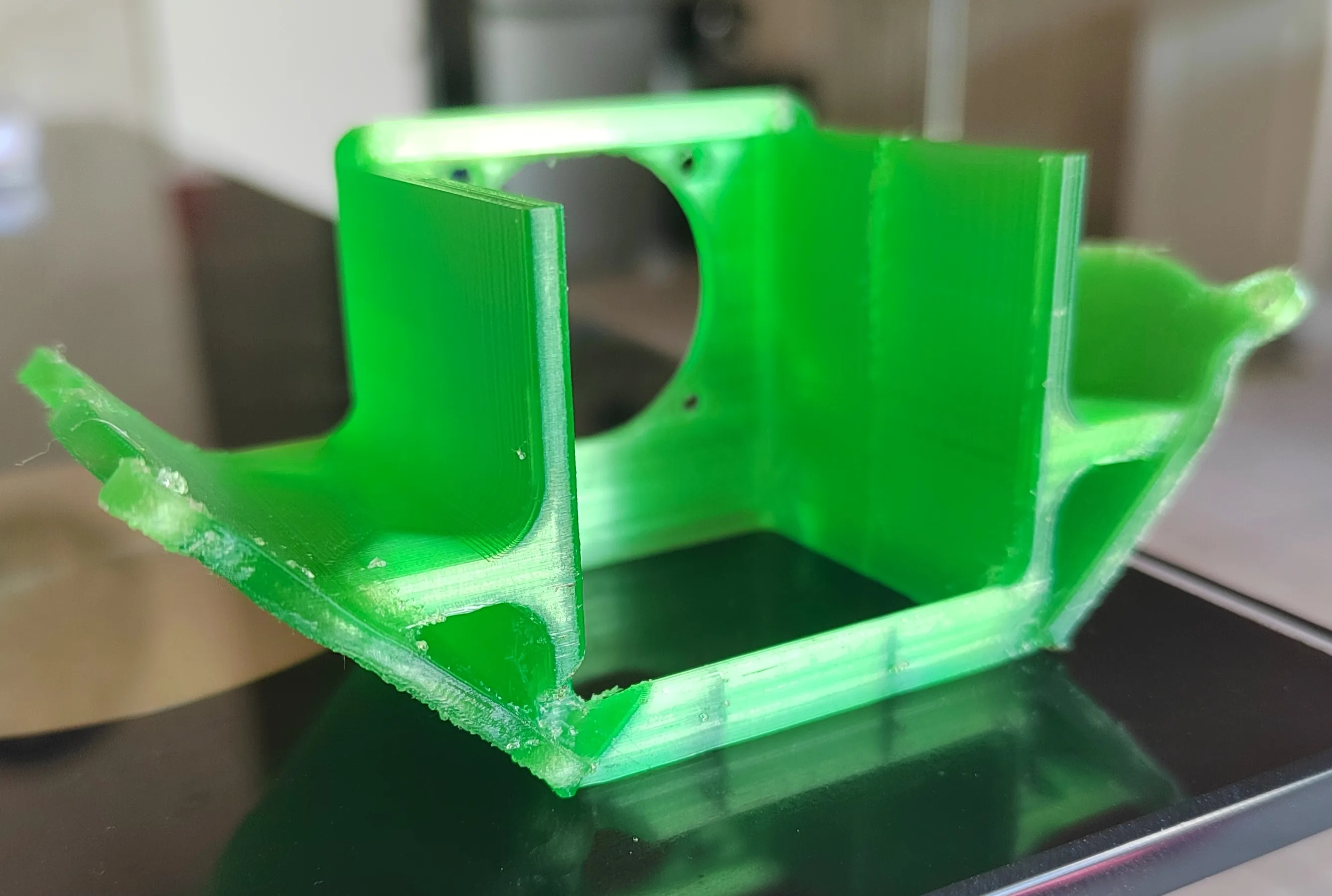

Feature 7 Easy Assembly

Easy assembly is a major selling point of the Tevo Tarantula Pro Kit, making it an accessible option for beginners and hobbyists. The kit is designed to be straightforward to assemble, with clear instructions and detailed diagrams. The assembly process typically involves attaching the frame components, connecting the motors and electronics, and installing the print bed and extruder. The kit includes all the necessary tools and hardware, minimizing the need for additional purchases. The modular design and pre-wired components simplify the assembly process. Detailed instructions and a well-organized kit will make the assembly a breeze. Many online resources, including video tutorials, are available. They can help users through each step of the assembly process. The ease of assembly reduces the barrier to entry for those new to 3D printing. It provides a satisfying experience of building a machine from scratch. Easy assembly allows users to quickly get their Tevo Tarantula Pro Kit up and running. It allows them to start creating 3D prints. This is a great starting point into the world of 3D printing. The easy-to-assemble design makes the Tevo Tarantula Pro an ideal choice for anyone looking for a hands-on 3D printing experience.

Step-by-Step Assembly Guide

The Tevo Tarantula Pro Kit comes with a detailed step-by-step assembly guide that walks users through the process of building their 3D printer. The guide typically starts with unpacking and inventorying all the components. This ensures that all parts are present and accounted for. The guide then breaks down the assembly into a series of logical steps. The steps usually involve assembling the frame, attaching the motors, connecting the electronics, installing the heated bed and extruder, and then connecting the power supply. Each step is accompanied by clear instructions and illustrations. It provides a visual reference for users to follow along. Many guides include helpful tips and warnings to prevent common mistakes. Online resources, such as video tutorials, often complement the written guide, providing a visual demonstration of each step. The step-by-step approach makes the assembly process approachable. It allows users to confidently build their 3D printer. The assembly process helps users understand the inner workings of the machine. It fosters a sense of accomplishment. The step-by-step guide is key to having a successful assembly.

Troubleshooting Common Assembly Issues

Even with a detailed assembly guide, users may encounter some common issues during the assembly of the Tevo Tarantula Pro Kit. Addressing these issues requires a problem-solving approach. Loose screws or connectors are a common issue. Tighten all screws and connectors. Make sure the connections are secure. Incorrect wiring can lead to the printer not functioning correctly. Refer to the assembly guide and wiring diagrams. Ensure that all wires are connected to the correct ports and terminals. Misaligned components can cause the printer to malfunction. Realign any misaligned components, such as the Z-axis lead screws or the print bed. The heated bed not heating up. Check the connections to the heated bed. Make sure that the power supply is properly set up. The motors not moving could be due to incorrect wiring or a faulty control board. Inspect the wiring. Check the motor drivers. The firmware not uploading properly. Ensure the correct firmware is installed. Troubleshooting guides and forums can also assist users in diagnosing and resolving these issues. Addressing these common assembly issues will ensure that the Tevo Tarantula Pro Kit is correctly assembled. It will also ensure the printer is ready to produce high-quality prints. Remember to document your progress and take breaks if you need them.