Understanding the Tevo Tarantula Stock Hotend

The Tevo Tarantula is a popular 3D printer known for its affordability and ease of use. However, the stock hotend, the component responsible for melting and extruding the filament, is often a point of concern for users looking to improve print quality and overall performance. Understanding the stock hotend is the first step towards making informed decisions about upgrades. This guide provides a comprehensive overview of the Tevo Tarantula’s stock hotend, its limitations, and how you can significantly enhance your 3D printing experience.

Stock Hotend Specifications

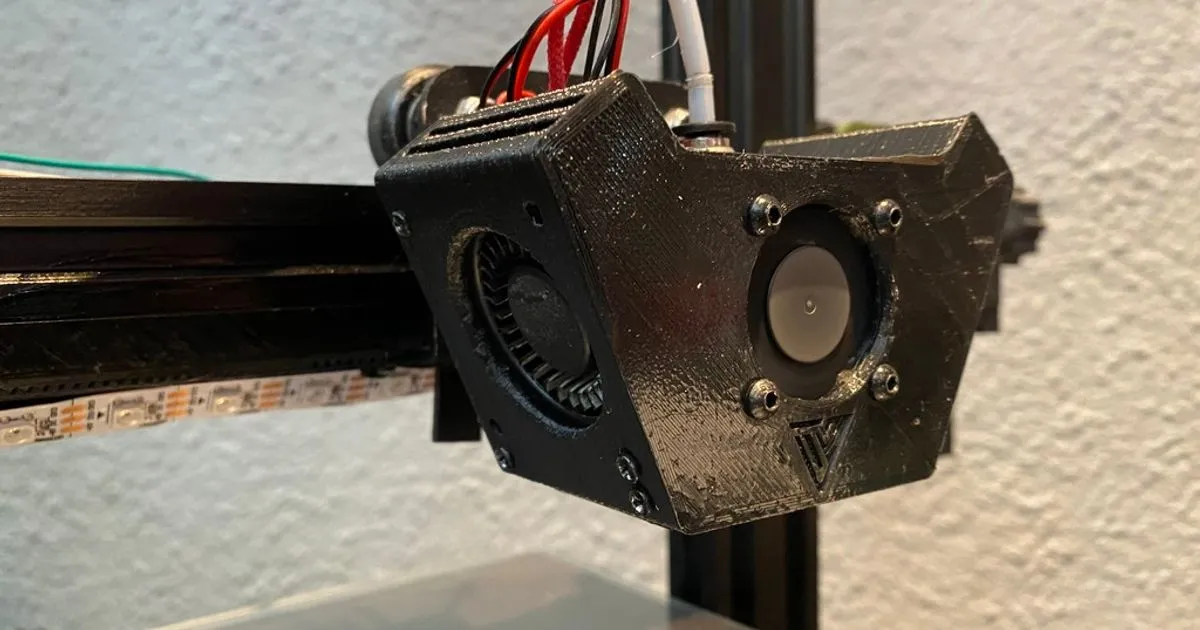

The stock hotend on the Tevo Tarantula typically features a PTFE-lined heat break, a brass nozzle, and a heating block. The PTFE lining is designed to prevent filament from sticking and ensure smooth extrusion. The brass nozzle is a common choice for its good thermal conductivity and affordability. These components work together to melt the filament and push it through the nozzle, allowing you to build your 3D printed objects layer by layer. However, while functional, the stock hotend has limitations that can hold back the printer’s full potential.

Limitations of the Stock Hotend

The primary limitation of the stock hotend is its temperature restriction due to the PTFE lining. PTFE, or Teflon, begins to degrade at higher temperatures, releasing potentially harmful fumes. This limits the types of filaments that can be used effectively, as some materials, such as ABS or nylon, require higher printing temperatures for optimal performance. Furthermore, the stock hotend can be prone to clogging, especially when printing at higher speeds or with abrasive filaments. This can lead to print failures and frustration. The heat break design can also contribute to heat creep, where heat travels up the hotend, causing filament to soften prematurely and potentially jam the nozzle.

Why Upgrade Your Tevo Tarantula Hotend?

Upgrading your Tevo Tarantula’s hotend can significantly improve your 3D printing experience, allowing you to achieve better print quality, print faster, and work with a wider range of materials. The benefits far outweigh the cost and effort of the upgrade. This section delves into the specific advantages of upgrading your hotend to help you decide if it’s the right choice for your needs. By understanding these advantages, you can make a more informed decision about which upgrade path is best for you.

Improved Print Quality

Upgrading to a high-quality hotend can lead to a noticeable improvement in print quality. Better temperature control, more consistent filament flow, and reduced clogging all contribute to finer details, smoother surfaces, and overall better-looking prints. Upgraded hotends often feature better insulation, which helps maintain a stable temperature, and improved heat break designs that minimize heat creep. This leads to more accurate layer adhesion and reduces common printing defects such as warping and stringing. The result is prints that are more visually appealing and have greater structural integrity.

Increased Printing Speed

A well-designed hotend can handle higher printing speeds without sacrificing quality. Upgraded hotends often have improved thermal characteristics, allowing them to melt filament more efficiently. This means you can increase your printing speed without encountering issues like underextrusion or failed prints. Faster printing speeds are particularly beneficial for larger projects or when you need to produce multiple prints in a short amount of time. However, it’s important to remember that print speed isn’t everything, and you should always prioritize print quality, especially when starting your upgrade. Using a faster hotend can decrease the print time significantly.

Wider Range of Filament Compatibility

One of the most significant advantages of upgrading your hotend is the ability to print with a wider variety of filaments. The stock hotend’s PTFE lining limits the maximum temperature, restricting the use of filaments like ABS, nylon, and polycarbonate, which require higher printing temperatures. Upgrading to an all-metal hotend eliminates this limitation, allowing you to print with a broader range of materials. This opens up new possibilities for your projects, allowing you to explore different properties like flexibility, strength, and temperature resistance. You will have more freedom to choose the perfect filament for your projects.

Hotend Upgrade Options for Your Tevo Tarantula

There are several hotend upgrade options available for the Tevo Tarantula, each with its own set of features and benefits. The right choice depends on your specific needs, budget, and printing preferences. This section explores the most popular upgrade options, including all-metal hotends, PTFE-lined hotends, and the differences between direct drive and Bowden systems. Understanding these options will help you make an informed decision and select the upgrade that best suits your needs. Considering all aspects of your 3D printing is important when choosing the correct hotend for you.

All-Metal Hotends

All-metal hotends are a popular upgrade choice, as they eliminate the PTFE lining, allowing for higher temperature printing. They typically feature a heat break made entirely of metal, such as stainless steel or titanium, which effectively separates the hot and cold zones of the hotend. This design allows for printing with materials that require high temperatures, such as ABS, nylon, and polycarbonate, and are less prone to clogging. All-metal hotends can also provide more precise temperature control and improved heat dissipation. They are a significant upgrade for users who want to expand their printing material options and improve overall print quality. Check compatibility to make sure it fits your Tevo Tarantula.

PTFE-Lined Hotends

PTFE-lined hotends offer an alternative upgrade path, especially for users who primarily print with lower-temperature materials like PLA and PETG. These hotends still use a PTFE lining, but they often feature improved heat break designs and better thermal management compared to the stock hotend. Upgrading to a PTFE-lined hotend can provide a noticeable improvement in print quality and reliability. PTFE-lined hotends are generally more affordable than all-metal options, making them a good choice for users on a budget. However, the temperature limitations of PTFE still apply, so they are not suitable for all filaments. Do not exceed the temperature limits for the PTFE tube.

Direct Drive vs Bowden Systems

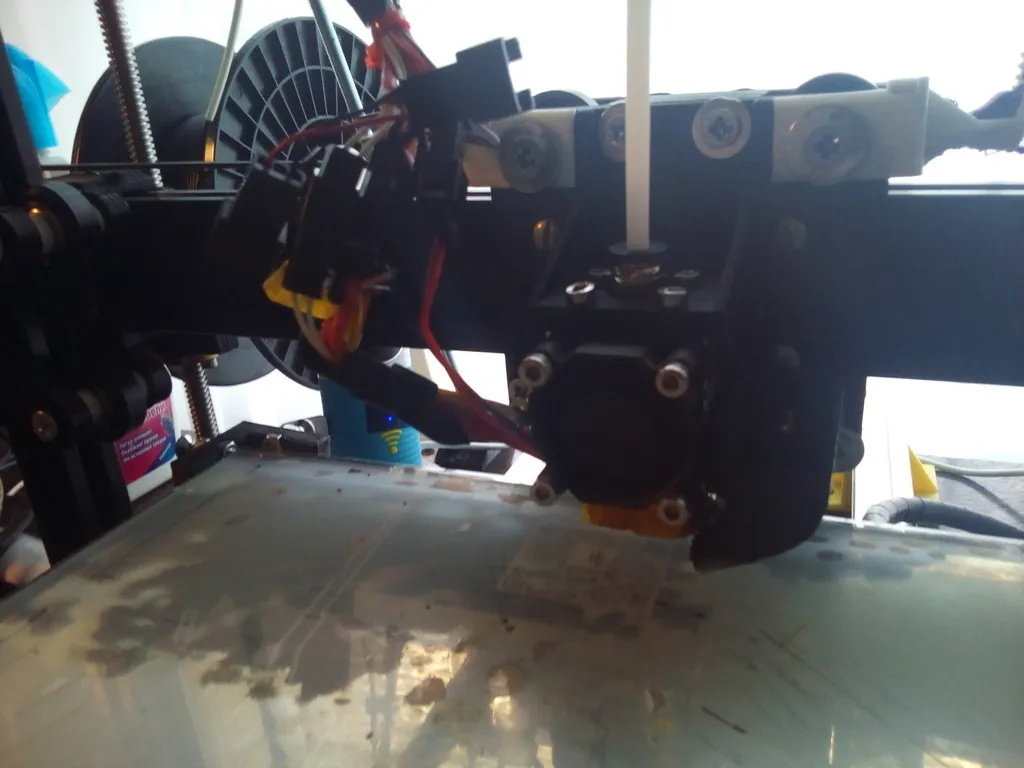

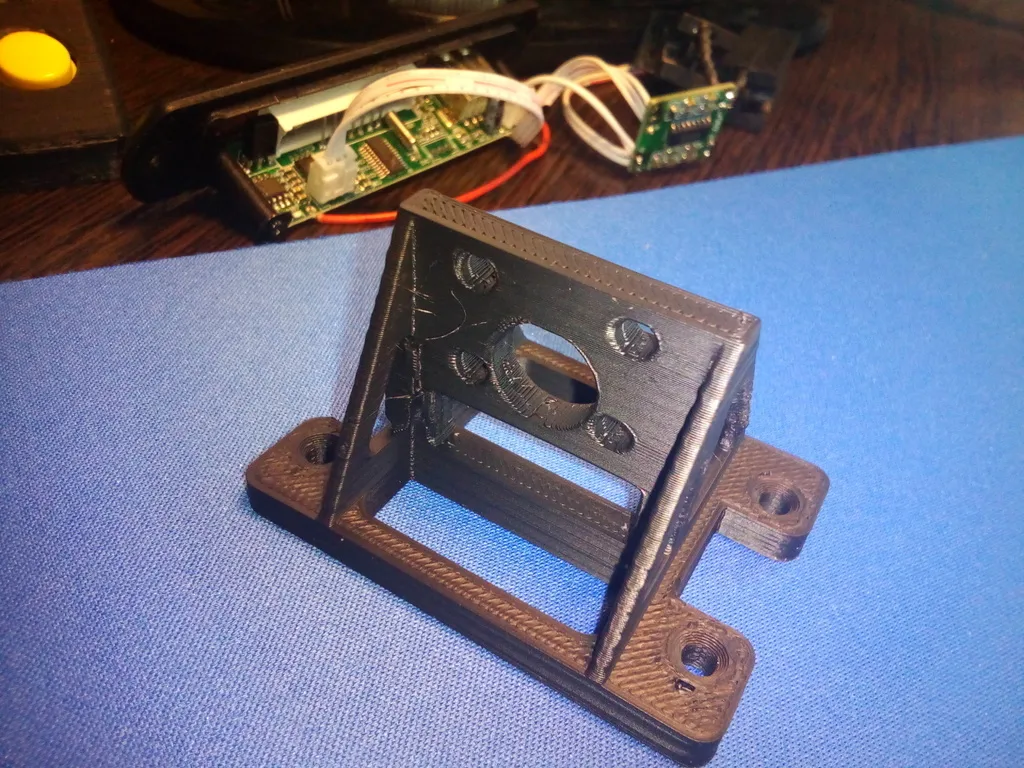

The Tevo Tarantula typically uses a Bowden system, where the extruder motor is mounted on the printer frame and the filament is fed through a PTFE tube to the hotend. Direct drive systems, on the other hand, mount the extruder motor directly on the hotend, reducing the distance the filament must travel. Direct drive systems can offer advantages such as improved retraction performance and the ability to print with flexible filaments more easily. However, they can also add weight to the print head, potentially affecting print speed and quality. Choosing between direct drive and Bowden depends on your printing needs and preferences. Each system has its advantages and disadvantages.

Choosing the Right Hotend for Your Needs

Selecting the right hotend upgrade requires careful consideration of your printing habits, budget, and desired outcomes. Understanding your specific needs will help you make an informed decision and choose the hotend that best suits your requirements. This section guides you through the key factors to consider when choosing a new hotend for your Tevo Tarantula, ensuring you make the best possible investment for your 3D printing setup. By taking the time to assess your needs, you’ll be much happier with the results.

Factors to Consider

Budget

The cost of hotend upgrades can vary significantly. All-metal hotends are often more expensive than PTFE-lined options. Set a budget before you start your search to narrow down your choices and avoid overspending. Consider the overall value, not just the initial cost. A slightly more expensive hotend with better performance and reliability may be a better investment in the long run.

Printing Needs

What types of filaments do you plan to print? If you mainly use PLA and PETG, a PTFE-lined hotend may be sufficient. However, if you want to print with high-temperature materials like ABS, nylon, or polycarbonate, an all-metal hotend is essential. Consider the complexity of your prints and the level of detail you desire. Also, consider how fast you wish to print. The more detailed the prints, the more your print time will increase. Determine the best route for your printing needs before purchasing.

Ease of Installation

Some hotend upgrades are easier to install than others. Consider your technical skills and comfort level with modifying your 3D printer. Some hotends come with detailed instructions and are designed for easy installation, while others may require more advanced knowledge and modifications. Research the installation process before purchasing and choose an option that you feel comfortable installing. Keep tools handy to expedite the install process. If you’re not comfortable with the installation process, consider seeking help from a friend, online forum, or 3D printing service.

Step-by-Step Hotend Upgrade Guide

Once you’ve selected your new hotend, the next step is installation. This section provides a step-by-step guide to help you upgrade your Tevo Tarantula’s hotend successfully. Always prioritize safety and follow the manufacturer’s instructions. This guide is a general overview, and your specific hotend may have different requirements. Double-check all connections and ensure everything is secure before powering on your printer. Make sure your printer is unplugged and turned off before working on it. Always ensure your printer is cold before any modifications.

Preparing Your Tevo Tarantula

Before you begin, ensure your printer is turned off and unplugged. Gather the necessary tools, including Allen wrenches, pliers, a screwdriver, and any tools that came with your new hotend. Refer to the manufacturer’s instructions for your specific hotend upgrade. It’s recommended to take photos of the existing setup before disassembling anything, which can be helpful during the reassembly process. Clear the area around your printer, making sure you have adequate lighting. This will prevent damage to your 3D printer or your new hotend during installation.

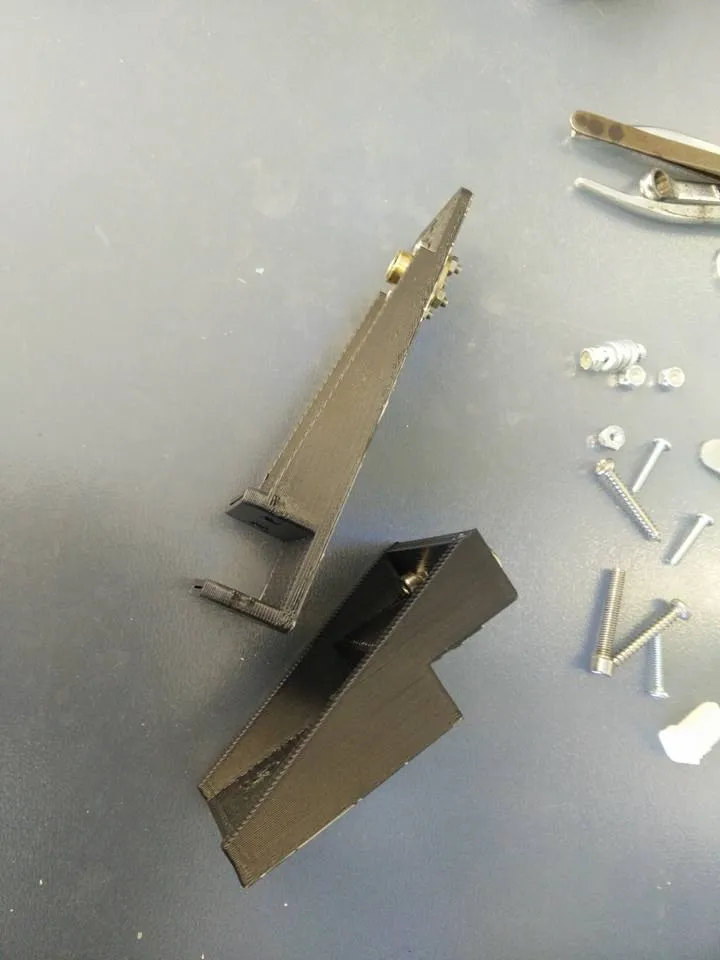

Disassembling the Stock Hotend

Carefully remove the fan shroud and any other components that cover the hotend. Loosen and remove the screws holding the hotend in place. Once the screws are removed, gently detach the wiring for the thermistor and the heater cartridge. Carefully remove the hotend from the printer. Next, remove the nozzle and the heat break. Be careful not to strip any screws. Consult your new hotend’s instructions on the best way to disassemble your stock hotend. Take pictures for future reference.

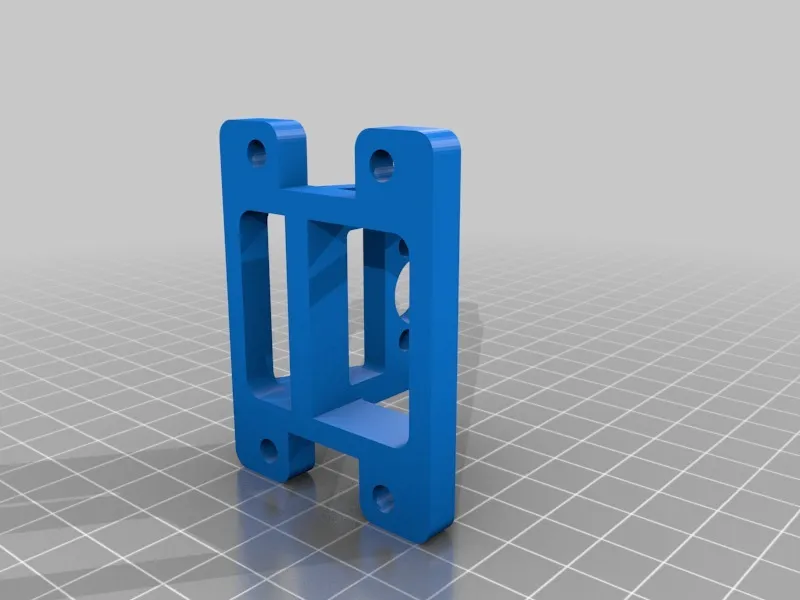

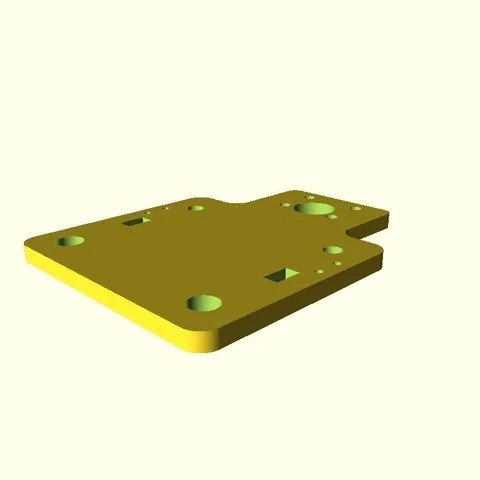

Installing the New Hotend

Install the new heat break and nozzle into the new hotend. Install the new hotend onto the printer, securing it with the appropriate screws. Reconnect the wiring for the thermistor and the heater cartridge. If you are changing to a different type of hotend, you may have to make minor adjustments to mounting hardware. Double-check all connections to make sure everything is secure. Refer to your new hotend’s instructions and any guides provided with your new hotend.

Calibrating and Tuning the New Hotend

After installing the new hotend, you’ll need to calibrate and tune it to ensure optimal performance. Perform a PID tuning of your hotend. Set the correct temperature settings for the filament you are using. Make sure you’ve leveled the bed correctly. You may also need to adjust the Z-offset. Run a few test prints to fine-tune your settings and dial in the perfect extrusion. Use a test print to make sure you get the desired outcome. Check for issues like stringing or warping, and adjust your settings accordingly. Once the prints are perfect, your hotend is ready for regular use.

Troubleshooting Common Issues

Even with a new hotend, you may encounter some issues. This section addresses some common problems and offers solutions to help you get back to printing quickly. The following are some of the issues you may face with your hotend.

Nozzle Clogging

Nozzle clogging is a common problem, often caused by incorrect temperatures, impurities in the filament, or a build-up of melted plastic. If you experience a clog, try increasing the temperature slightly or using a nozzle cleaning tool. You can also try performing a cold pull, where you heat the hotend, manually extrude filament, and then cool the hotend to remove the clog. Make sure your filament is clean, and store it in a dry environment to prevent moisture absorption, which can also cause clogs. Sometimes, cleaning the nozzle can be as easy as using a needle.

Extrusion Problems

Extrusion problems can manifest as underextrusion, where not enough filament is extruded, or overextrusion, where too much filament is extruded. Check your extruder settings, including the E-steps, to ensure they are calibrated correctly. Make sure that the nozzle is the correct distance from the print bed. Verify the temperature and adjust as necessary. Ensure your filament isn’t getting caught. A clogged nozzle can also cause extrusion problems. Make sure that you have the right settings for the filament that you are printing.

Temperature Issues

Inconsistent temperatures can lead to poor print quality and failed prints. Check that your thermistor is properly connected and that your printer is accurately reading the temperature. If you notice temperature fluctuations, try re-calibrating your PID settings. Make sure the hotend is properly insulated and not exposed to drafts. Ambient temperature plays a role in the printed material. Adjust the ambient temperature to optimize your prints.

Maintenance and Care for Your Upgraded Hotend

Proper maintenance and care are crucial for the longevity and performance of your upgraded hotend. Following these tips will ensure that your hotend continues to deliver high-quality prints for years to come. Proper maintenance can minimize potential issues with your hotend.

Regular Cleaning

Regular cleaning is essential. Remove any filament residue from the nozzle and heat block after each print. Use a brass brush to remove any debris. Avoid using excessive force that could damage the hotend. Consider using a nozzle cleaning kit for more thorough cleaning. Keeping your hotend clean ensures that it performs at its best. Clean your hotend regularly to get the best performance.

Preventative Maintenance

Perform regular inspections. Check the connections and the wiring for any signs of wear and tear. Tighten screws as needed. Consider replacing the nozzle periodically. Store filament properly to prevent moisture absorption and clogs. Make sure your printer is in an area that is not subject to large temperature fluctuations. Preventative maintenance can help eliminate issues and prolong the life of your 3D printer.

Final Thoughts and Next Steps

Upgrading your Tevo Tarantula’s hotend is a rewarding endeavor that can significantly enhance your 3D printing experience. By understanding the stock hotend’s limitations, exploring upgrade options, and following the installation and maintenance steps outlined in this guide, you can achieve better print quality, increase printing speeds, and expand your filament choices. Remember to choose the upgrade that best suits your printing needs and always prioritize safety. Embrace the possibilities and enjoy the exciting world of 3D printing with your newly upgraded Tevo Tarantula. Enjoy printing with your new hotend!