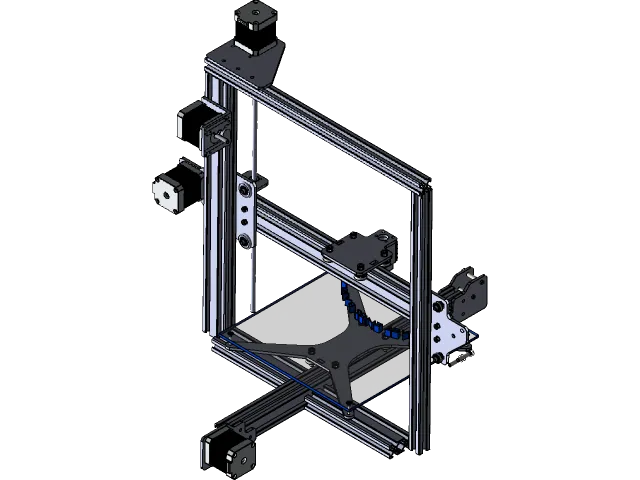

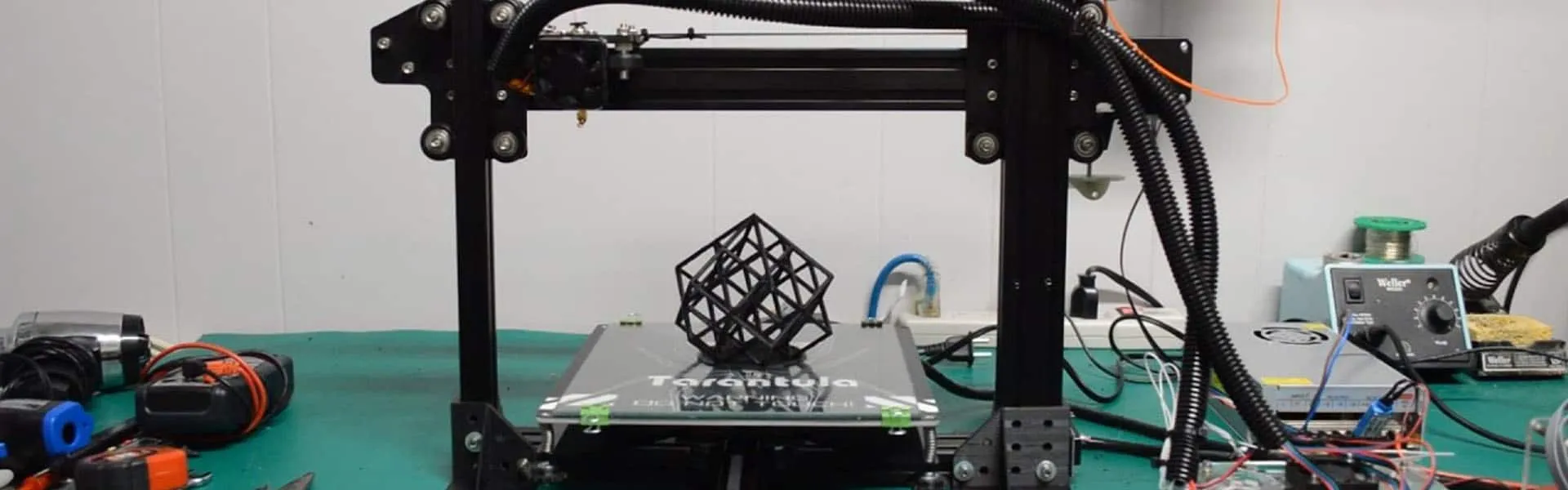

The Tevo Tarantula is a popular DIY 3D printer known for its affordability and open-source nature. Its electronics are the heart of its operation, controlling every aspect of the printing process, from heating the nozzle to moving the print head. Understanding the key electronic components and their functions is crucial for anyone looking to build, operate, or troubleshoot this 3D printer. This guide will explore the top 7 features of the Tevo Tarantula’s electronics, providing a comprehensive overview for both beginners and experienced users. Delving into these elements helps you to optimize print quality, understand potential issues, and perform upgrades, ensuring your 3D printing experience is smooth and successful.

Main Electronics Components

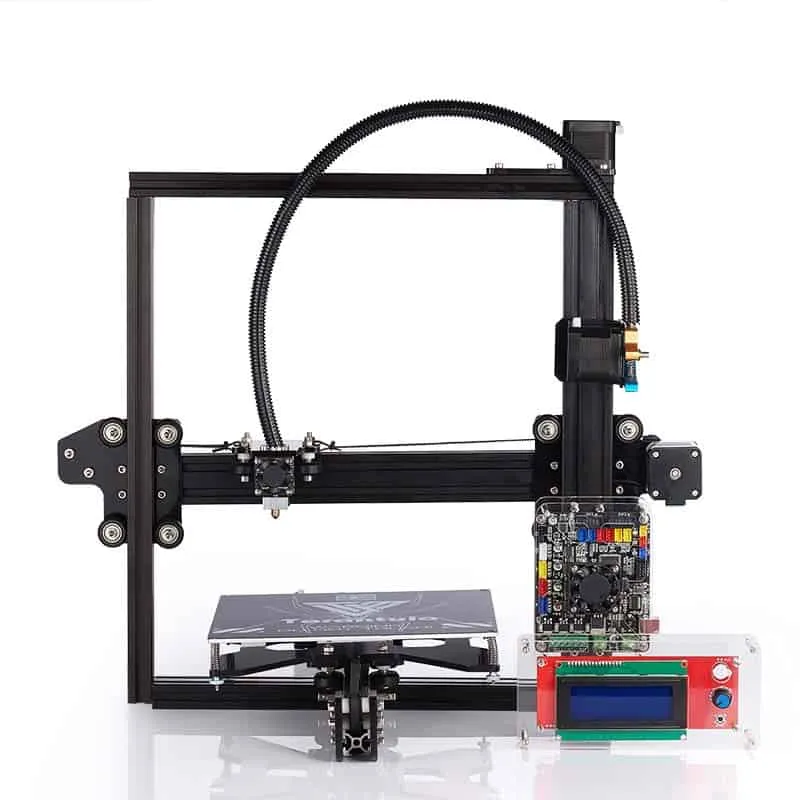

The Tevo Tarantula’s electronics consist of several interconnected components that work in harmony to bring your 3D models to life. These elements manage power distribution, motion control, temperature regulation, and user interface. Understanding each of these components and its function is key to operating and maintaining the printer. The following sections will delve into each of these key elements, explaining their role within the printing process and how they contribute to overall functionality. From the motherboard to the power supply, and the stepper motors to the heated bed, each piece plays a critical role in the performance of your Tevo Tarantula.

The Motherboard

The motherboard is the central processing unit of the Tevo Tarantula, serving as the control center for all operations. It houses the main microcontroller, typically an Arduino-based board, which interprets G-code instructions from the computer or SD card and translates them into actions for the printer. The motherboard also manages communication with other components, such as the stepper motor drivers, the heated bed, and the LCD screen. It is crucial to select a motherboard that’s compatible with the printer’s firmware and that has enough processing power and memory to handle complex prints. The motherboard’s performance directly affects print quality and overall printer responsiveness.

The Power Supply

The power supply unit (PSU) provides the necessary electrical power to all the electronic components of the Tevo Tarantula. It converts the mains AC power into the DC voltage required by the printer. A reliable power supply is essential for consistent performance and safety. It’s crucial to ensure the power supply is adequate for the printer’s requirements, including the heated bed, which can draw significant power. Overloading the power supply can lead to inconsistent heating, print failures, and even damage to the electronics. Choosing a PSU with appropriate wattage and safety certifications is critical for a safe and dependable 3D printing setup.

The LCD Screen and Controller

The LCD screen and its associated controller provide the user interface for the Tevo Tarantula. They allow you to navigate menus, select print files from the SD card, control temperatures, and monitor the printing progress. This interface is generally a character-based LCD, but some users upgrade to graphic LCD screens for a more intuitive experience. The controller board interfaces with the motherboard, receiving commands and displaying information about the print. Ensuring the LCD screen is correctly connected and configured within the printer’s firmware is critical for a seamless user experience and efficient control over print settings. Proper calibration and clear display information improve the user experience.

The Stepper Motors and Drivers

Stepper motors are responsible for the precise movement of the print head and the heated bed. They are controlled by stepper motor drivers, which translate signals from the motherboard into the specific movements needed to print a 3D model. These drivers control the current to the stepper motors, enabling them to rotate in small, controlled steps, delivering accuracy in the X, Y, and Z axes, as well as the extruder. The quality of the stepper motors and drivers significantly affects the print quality, layer adhesion, and overall smoothness of the print. Upgrading the stepper motors or drivers can improve print quality and reduce noise during operation.

Extruder and Hotend

The extruder and hotend are vital parts of the printing process. The extruder pushes the filament through the hotend, where it’s melted and deposited onto the print bed. The hotend includes a heater cartridge and a thermistor to maintain the correct temperature. The temperature is crucial for ensuring that the filament melts properly without burning. Accurate temperature control and consistent filament flow are essential for successful prints. Regular maintenance, including cleaning the hotend and checking the thermistor, is essential for print quality. Upgrading the hotend allows for higher printing temperatures and a wider range of compatible filaments.

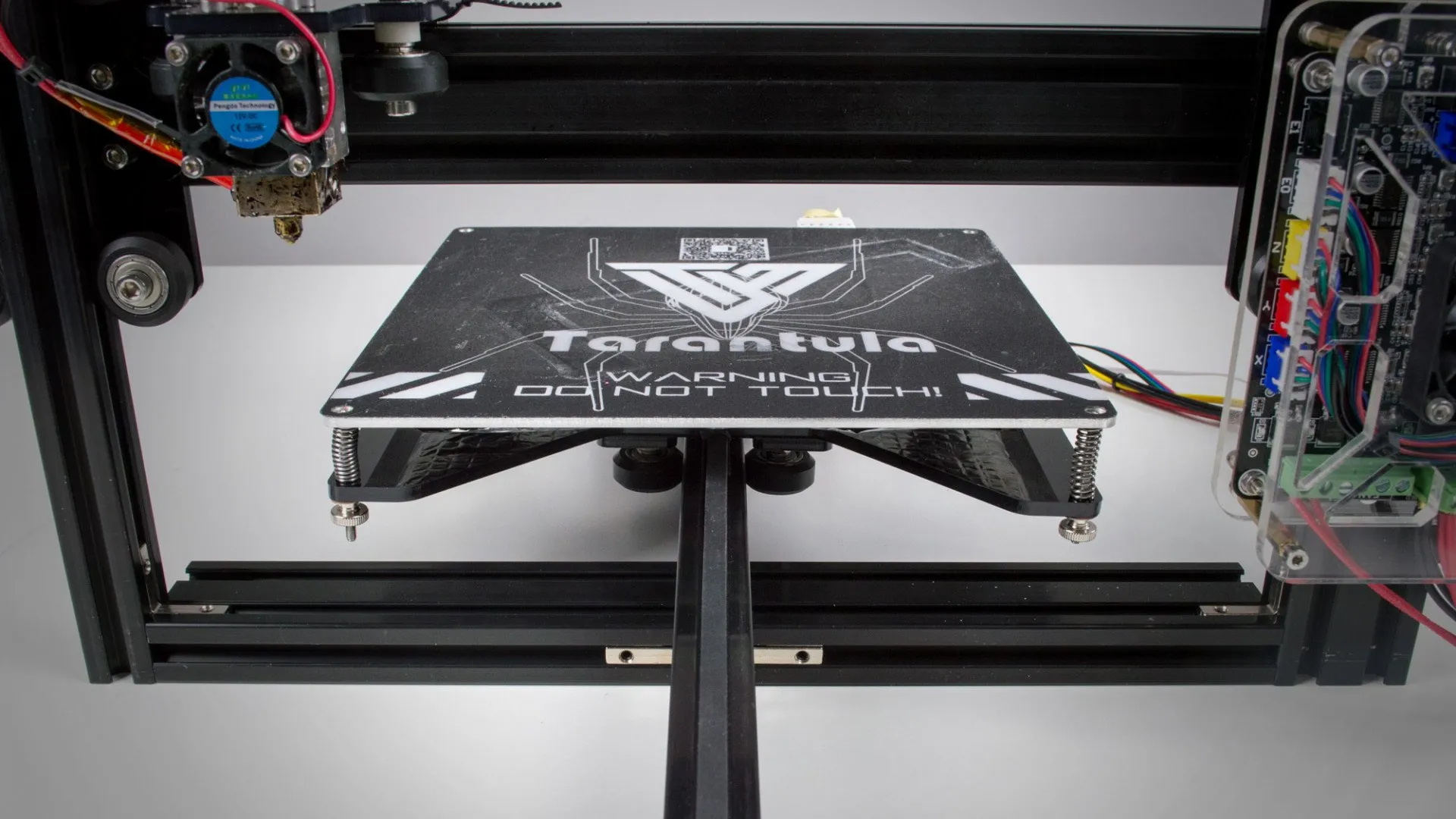

The Heated Bed

The heated bed is a critical component, especially when printing with materials like ABS. It provides a consistent temperature, helping the first layer of the print adhere to the bed. This ensures that the print remains in place during the printing process and minimizes warping. The heated bed usually consists of a heated plate and a temperature sensor (thermistor) to monitor and control the temperature. The quality of the bed and the accuracy of its temperature regulation can significantly affect print quality. A well-calibrated and maintained heated bed guarantees excellent bed adhesion. This helps you to reduce the probability of print failures.

Firmware and Software

Firmware and software are the brains of the Tevo Tarantula, controlling the printer’s operations and coordinating the various electronic components. They determine how the printer interprets G-code instructions, controls the movement of the print head, regulates temperatures, and much more. Understanding the basics of firmware and software, and how they work, is vital for customizing your printer and optimizing print performance.

Essential Software for Tevo Tarantula

Several software tools are essential for using the Tevo Tarantula. Slicing software, such as Cura or PrusaSlicer, converts 3D models into G-code, a language the printer understands. This software is key to managing print settings, generating support structures, and preparing the model for printing. Firmware, typically Marlin, is the operating system that runs on the printer’s motherboard, controlling the printer’s hardware. Software like Pronterface helps to send G-code to the printer and monitor its progress. These software tools provide you with a comprehensive workflow from model design to physical object.

Understanding Firmware

Firmware is the software that controls the hardware of your 3D printer. It manages tasks, such as temperature control, motor movement, and communication with the user interface and SD card. Marlin is the most popular firmware used by the Tevo Tarantula and offers extensive customization options. Understanding how to configure and update the firmware is crucial for optimizing print settings, fixing issues, and adding new features. The firmware determines the printer’s behavior and responsiveness, so maintaining the correct firmware is crucial to ensure a great printing experience.

Connectivity and Communication

Establishing proper connectivity and communication between your computer and the Tevo Tarantula is essential for printing, monitoring, and making adjustments. This usually involves connecting via USB or using an SD card to transfer print files. Successfully establishing communication ensures that you can control the printer, upload print jobs, and monitor progress. Troubleshooting communication issues is a fundamental skill for 3D printer users.

Connecting to your Computer

Connecting your Tevo Tarantula to your computer allows you to control the printer and upload print files directly. The primary method for connecting is usually via a USB cable. You’ll need to install the appropriate drivers for your printer to be recognized by your computer. Once the printer is connected, you can use software like Pronterface or Repetier-Host to send G-code files, monitor the printing process, and make real-time adjustments. Ensuring a stable USB connection is crucial to avoid print interruptions.

SD Card Usage

The SD card provides a convenient way to transfer print files to your Tevo Tarantula. You prepare the G-code files using slicing software and then save them to the SD card. Insert the SD card into the printer and select the print file from the LCD screen. This method is very reliable because it eliminates the need for a constant connection to your computer. Using an SD card is particularly useful if you prefer to avoid using a dedicated computer or when printing complex designs that might overload your PC’s resources. The SD card’s functionality enables you to print autonomously.

Upgrading Your Electronics

Upgrading the electronics of your Tevo Tarantula can enhance its performance, add new features, and improve print quality. These upgrades range from simple component replacements to more complex modifications. Before upgrading, it’s important to understand the benefits of each potential upgrade and consider your specific printing needs.

Why Upgrade

Upgrading your Tevo Tarantula’s electronics can lead to improvements in several key areas. Enhanced print quality is a primary reason, as better stepper motor drivers can reduce noise and improve accuracy. Increased printing speeds can reduce print times, while more advanced features, such as automatic bed leveling, simplify the printing process. Upgrades can also add support for a wider range of materials and improved temperature control. Careful upgrades can make your Tevo Tarantula more reliable, efficient, and versatile, leading to a better overall 3D printing experience. Many upgrades also extend the lifespan of the printer.

Upgrade Options

Several upgrade options are available for the Tevo Tarantula’s electronics. You can upgrade the motherboard for a more powerful processor or to support advanced features. Switching to higher-quality stepper motor drivers will improve print quality. Adding a more powerful or efficient power supply will enhance reliability and performance. Installing a better hotend will allow you to print at higher temperatures, expanding the range of compatible filaments. The LCD screen and its controller can also be upgraded. The choice of upgrades depends on your printing needs. It is important to research each upgrade and ensure it is compatible with your existing setup.

Safety Precautions

Safety should be a top priority when working with the Tevo Tarantula’s electronics. The printer operates with electricity and can reach high temperatures, so it’s crucial to follow safety guidelines to prevent accidents and injuries. Always disconnect the printer from the power source before performing any maintenance or upgrades. Familiarize yourself with the components and their functions before making any adjustments. By exercising caution and being aware of potential hazards, you can ensure a safe and enjoyable 3D printing experience.

- Always unplug the printer before working on its electronics

- Avoid touching hot components like the hotend and heated bed

- Ensure all wiring connections are secure to prevent shorts

- Use appropriate safety gear, like gloves, when necessary

- Never leave the printer unattended while printing

- Keep flammable materials away from the printer

- Regularly inspect the wiring for any signs of wear or damage

In conclusion, the electronics of the Tevo Tarantula are fundamental to its operation and success. Understanding these components empowers you to build, maintain, troubleshoot, and upgrade your printer to meet your specific needs. By mastering the key features and understanding the critical components, you’ll be well-equipped to create high-quality 3D prints and enjoy the full potential of this versatile machine. Continuous learning and hands-on experience are the best ways to master the intricacies of 3D printer electronics and take your skills to the next level. Take the time to learn and experiment. The more you learn, the more you will enjoy your Tevo Tarantula.